In our last newsletter, I wrote about the average speeds of motocross suspension on a hardpack circuit. There were some surprising values in there, including max speeds of up to 7.1m/s on the forks, and 2.3m/s on the shock. This brings up the question then, is it worth it to use a shock dyno in motocross?

The reason being that most shock dynos on the market have a maximum speed of 2.5m/s to 3m/s, and many times suspension technicians will run their tests at 1m/s. That’s surely a problem, isn’t it? How can a technician be sure that what they change on the shim stack is having the desired effect on the track?

There are two things we need to find out:

Can a dyno be run at their maximum speed of 3m/s with motocross suspension?

And, how much time does the suspension spend above 3m/s on the track?

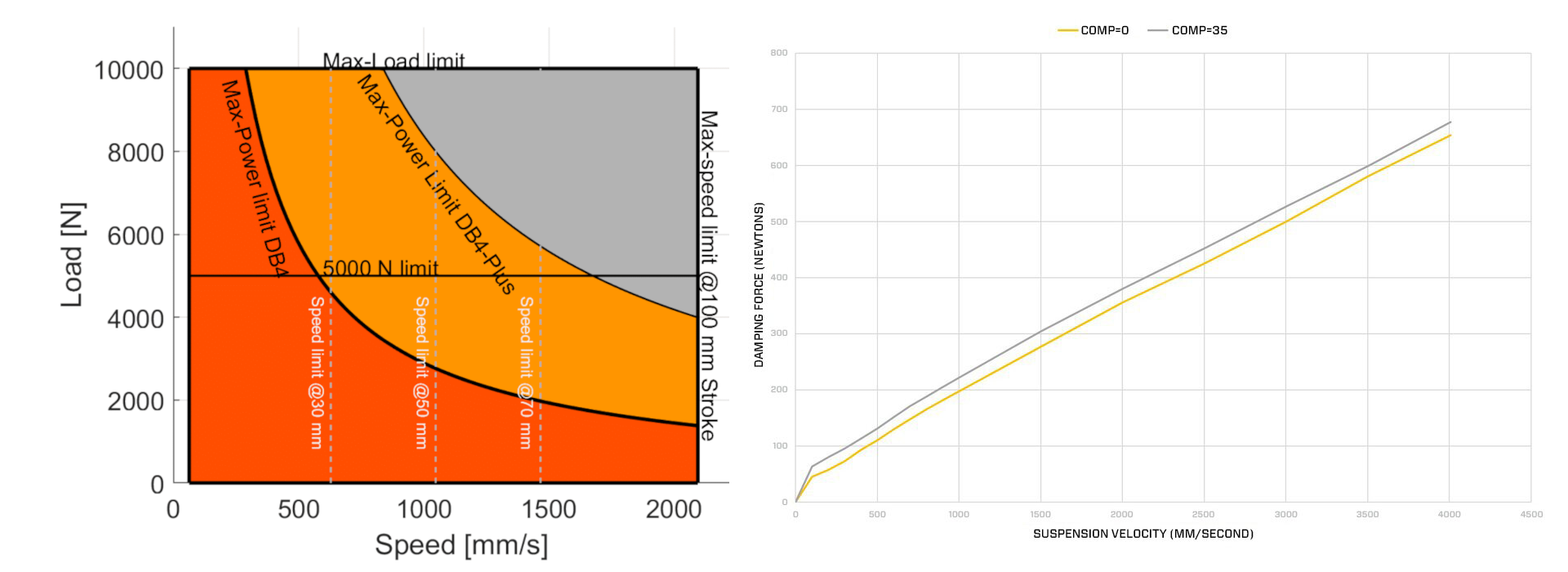

In the image above on the left are the specifications of the Andreani DB4 and DB4-Plus dynamometer’s, and on the right is a force vs speed graph for standard WP XACT fork suspension from the Kreft suspension website.

For the most part, the type of dynos you will find with a motocross suspension technician are Scotch-Yoke or Crank dyno’s, and you can read about the Pro’s and Con’s of each on Laba 7’s website.

What’s being shown in the Andreani graph is that with the DB4 dyno, the suspension can only produce a force of 2,000 Newtons at 2m/s.

On the Kreft moto graph, it shows the measured force of the fork vs the speed. The speed goes up to a max of 4m/s, and the force at that point is slightly less than 700N.

That all seems fine then, the fork can be ran at maximum speed on this dyno.

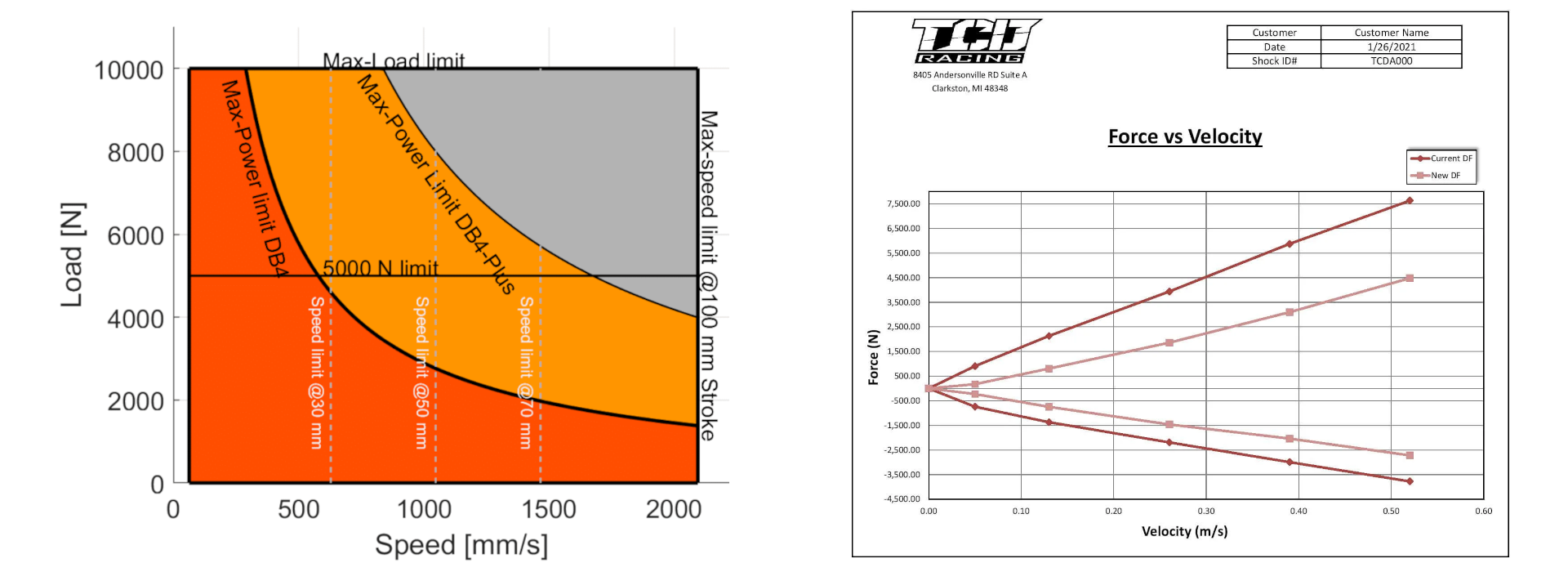

In the image above on the left are the specifications again of the Andreani DB4 and DB4-Plus dynamometer’s, and on the right is a force vs speed graph for a Showa shock on the TCD Racing website.

On the TCD Racing graph, it shows the measured force of the shock vs the speed for both compression and rebound. The upward trending lines are the compression values which are the focal point of this article. The max force measured is 7,500N with the standard shim settings, and only at a speed of 0.52m/s. With the shim stack adjustments made by TCD, this value is dropped to 4,500N

Even with the softer TCD settings, this means that by the time the DB4-Plus dyno gets to 0.7m/s or 0.8m/s, it could already be at its limit. Now, I’m not pointing a finger at the DB4-Plus, it could very well be the same issue with most dynos that are used, it is just that Andreani were open enough to provide this information on their website, and it’s all I have to work off.

What about the answer to our first questions, can dyno’s be ran at their maximum speed with motocross suspension?

For the forks, we can likely say yes. For the shock, it’s a maybe leaning towards a probably not. It really depends on the stiffness of the shim stack and valving setup in the shock.

But does that really matter if we compare it to real world data? Let’s have a go at answering our second question.

Throughout these articles, I have been using the same data set for each example. The data comes from a German hard pack track, with a young rider on a 2023 Husqvarna TC 250.

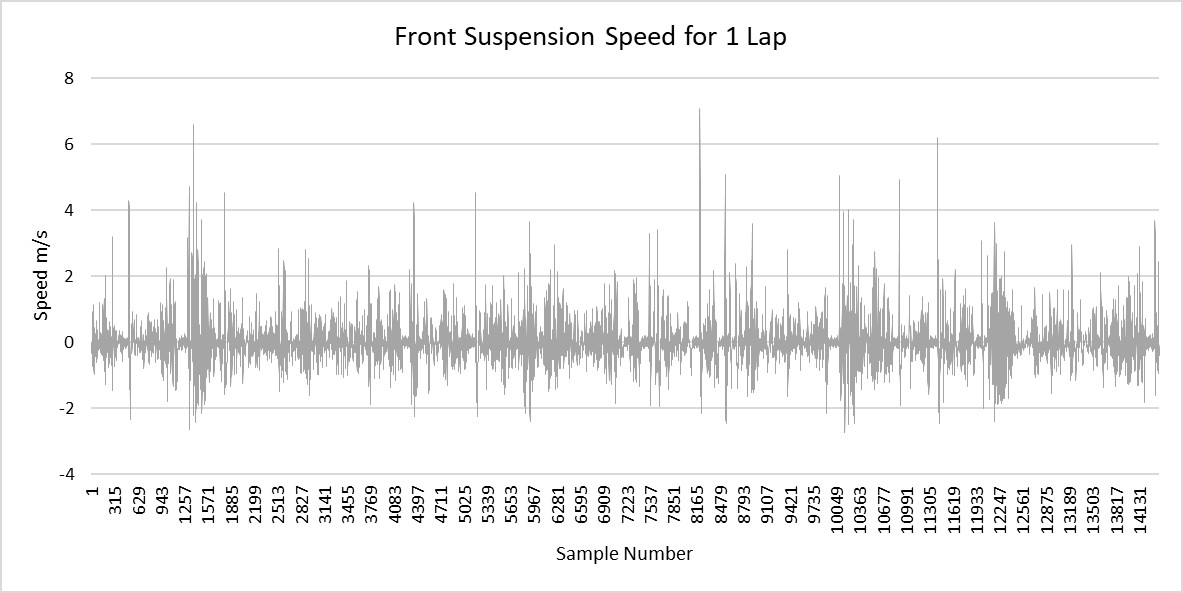

You will have seen the graph above before in our previous article on improving the accuracy of our predictions for suspension setup. It shows the speed of the forks throughout the entire session, which was around 3 laps long. We found out in our last article on average suspension speed that the suspension moves fastest on jump take off’s and particularly landings.

We can see a number of times where the suspension reaches speeds far higher than the max speed for most dyno’s of 3m/s, but how often does it move that fast really?

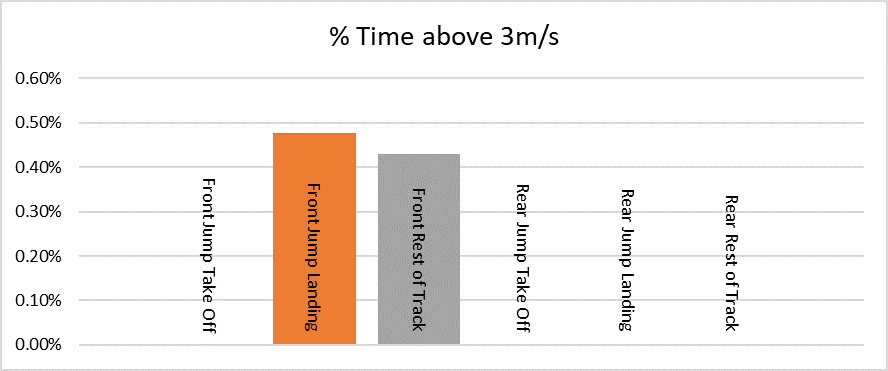

I have broken the data out for the front and rear and calculated what percent of time is spent above 3m/s for the forks and shock.

The total time the forks spend above 3m/s is 0.91%.

The total time the shock spends above 3m/s is 0.00%.

Yippee! This means that measuring the suspension at the max speed on the shock dyno doesn’t bring us an awful lot of value, and probably isn’t worth worrying about. Remember, on the rear shock, we extrapolated that the max speed would probably be around 0.8m/s.

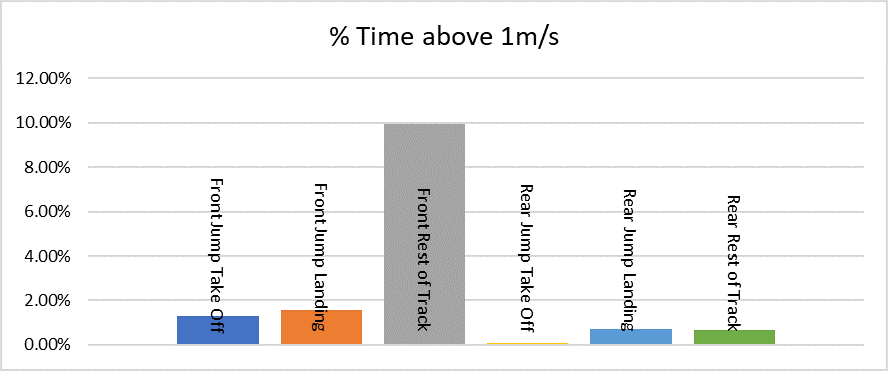

However, from speaking with suspension technicians, I know that many of them run their dyno’s at 1m/s. So let’s carry out the same analysis again, and find out how much percent time the suspension spends above 1m/s.

The total time the forks spend above 1m/s is 12.76%.

The total time the shock spends above 1m/s is 1.45%.

13% is a pretty significant amount of time to ignore, but we also know now that the dyno should be able to run forks at max speed because the damping force is low enough.

What does all this mean then.

The bottom line is, the higher end dyno’s that are available on the market should be satisfactory to cover 99% of the time the suspension spends moving in the real world, but you have to be careful about the maximum force for the rear shock. If you’re a technician that is working with supercross suspension, there could be some real challenges if the dyno isn’t up to the specification you need.

Something else to watch out for here, is that this is only one example with some pretty big assumptions about the damping forces created by the suspension, and data from just one session on one track. There can be a lot of variables that skew the outcome of this study one way or the other.

There is no doubt that dyno’s are an excellent tool for performing quality assurance checks, as well as optimising the damping characteristic for different type’s of riders. Even if you want to see what the force curve is at the max fork speeds of 7m/s that we saw in the first graph, by running the dyno at max speed of 3m/s, you could probably have a good guesstimate at what the damping curve looks like.

If you want to work with the Motoklik system, you can email [email protected] with any questions you have.

Kind Regards,

Jens